Bio-Inspired Robotic Arm

Design, fabrication, and control of a cable-driven continuous backbone manipulator inspired by the logarithmic spiral geometry of octopus tentacles.

View Full Report →Biomimicry in Action

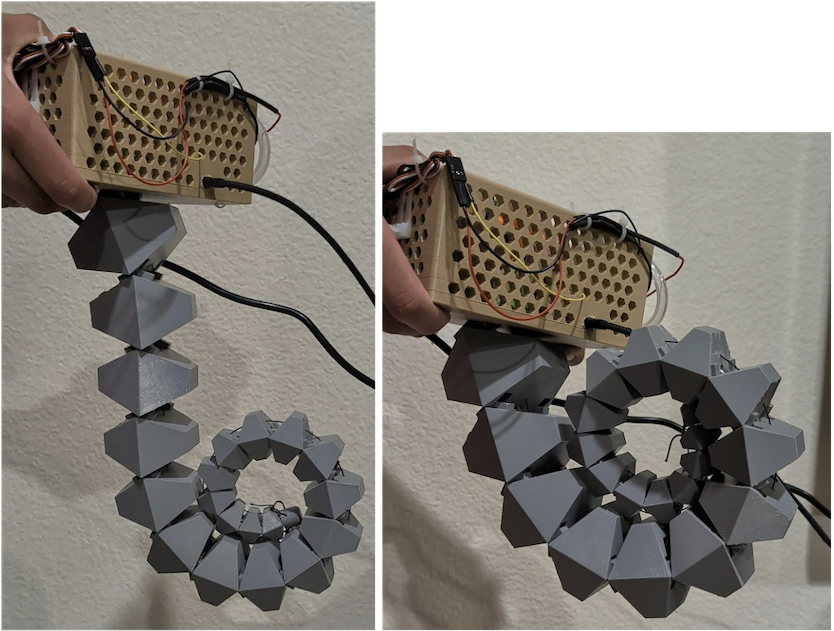

Unlike traditional robots with discrete rigid joints, this arm utilizes a continuous backbone to achieve smooth curling motions. The goal was to create a low-cost, modular platform capable of high-articulation grasping using FDM 3D printing.

By leveraging a logarithmic spiral geometry, the arm can wrap tightly around objects of varying sizes, maintaining a constant grasping angle regardless of the target's diameter.

Mechanical Design & Geometry

The system relies on a series of discrete tapered units, scaled mathematically to ensure the arm curls from the tip (lowest stiffness) to the base (highest stiffness).

The Logarithmic Spiral

-

Mathematical Foundation

The arm geometry is defined by the polar equation:

\[ \rho = ae^{\beta\theta} \]Where \(\beta=0.94\) controls the growth rate. This ensures a constant grasping angle, allowing versatile wrapping around both thin cables and large cylinders.

-

Torsion Control

To prevent unwanted twisting, each unit features interlocking hexagonal keys (2 notches and 2 grooves). This constrains the assembly to curl only in the intended plane while allowing a 50° total bending angle.

Electronics & Control

A high-torque system driven by an Arduino R4 WiFi and a custom-designed winch mechanism.

Actuation & Power

The core actuator is a 55kg-cm continuous rotation servo acting as a winch. It pulls a UHMWPE braided line running through the perimeter of the units. Due to high current draw (5-7A), the motor is isolated on a dedicated 5V 15A PSU.

Safety Control

Since continuous servos lack position feedback, I implemented a "dead man's switch" using Processing. The arm only curls while the 'W' key is held and stops instantly upon release to prevent over-tightening.

Results & Challenges

Iterative engineering was required to solve mechanical failures and achieve a working prototype.

The "Lifting" Issue

Ideally, the arm curls. In reality, friction caused the winch to pull the entire arm upwards bodily.

Solution: A custom housing was designed to rigidly anchor the base, forcing the energy into the curling motion.

Winch Slip

The 55kg-cm torque stripped the plastic-on-metal press fit of the printed winch.

Solution: Implemented a zip-tie reinforced mounting system to mechanically bind the spool to the servo horn.

Final Outcome

The final prototype successfully curls the full 20-unit assembly. The central elastic tube returns the arm to straightness, and the hexagonal geometry effectively prevents torsion.

Future Improvements

- Reduce stiffness of the inner tube for tighter curling.

- Design a housing that supports motor torque without zip-ties.

- Add a second degree of freedom for 3D curling (not just planar).

- Mount on a drone for aerial retrieval tasks.