Kinetic Sculpture: A Symphony in Motion

A fun team project to design and build a kinetic sculpture powered by a belt-driven motor, all fitting within a compact space.

Read the Project Report →The Project Objective

The main goal was to work as a team to create a visually engaging kinetic sculpture. The key constraints were that the motion had to be driven by a single motor via a belt-drive system, and the entire sculpture had to be contained within a 12" x 12" x 5" volume.

Belt-Driven Motion

The sculpture's movement had to originate from a single DC motor and be transmitted via a belt drive.

Complex Movement

The design needed to produce an interesting, multi-layered motion from the single power source.

Compact Design

The entire assembly was required to fit within a strict 12" x 12" x 5" volume.

A Collaborative Creation

Our team's vision was to create a mesmerizing, layered motion using a series of gears. The project became a comprehensive exercise in integrating various manufacturing techniques to bring a dynamic piece of art to life.

It challenged us to blend creative design with precise engineering, managing power transmission, material selection, and assembly within tight constraints.

The Mechanical Design

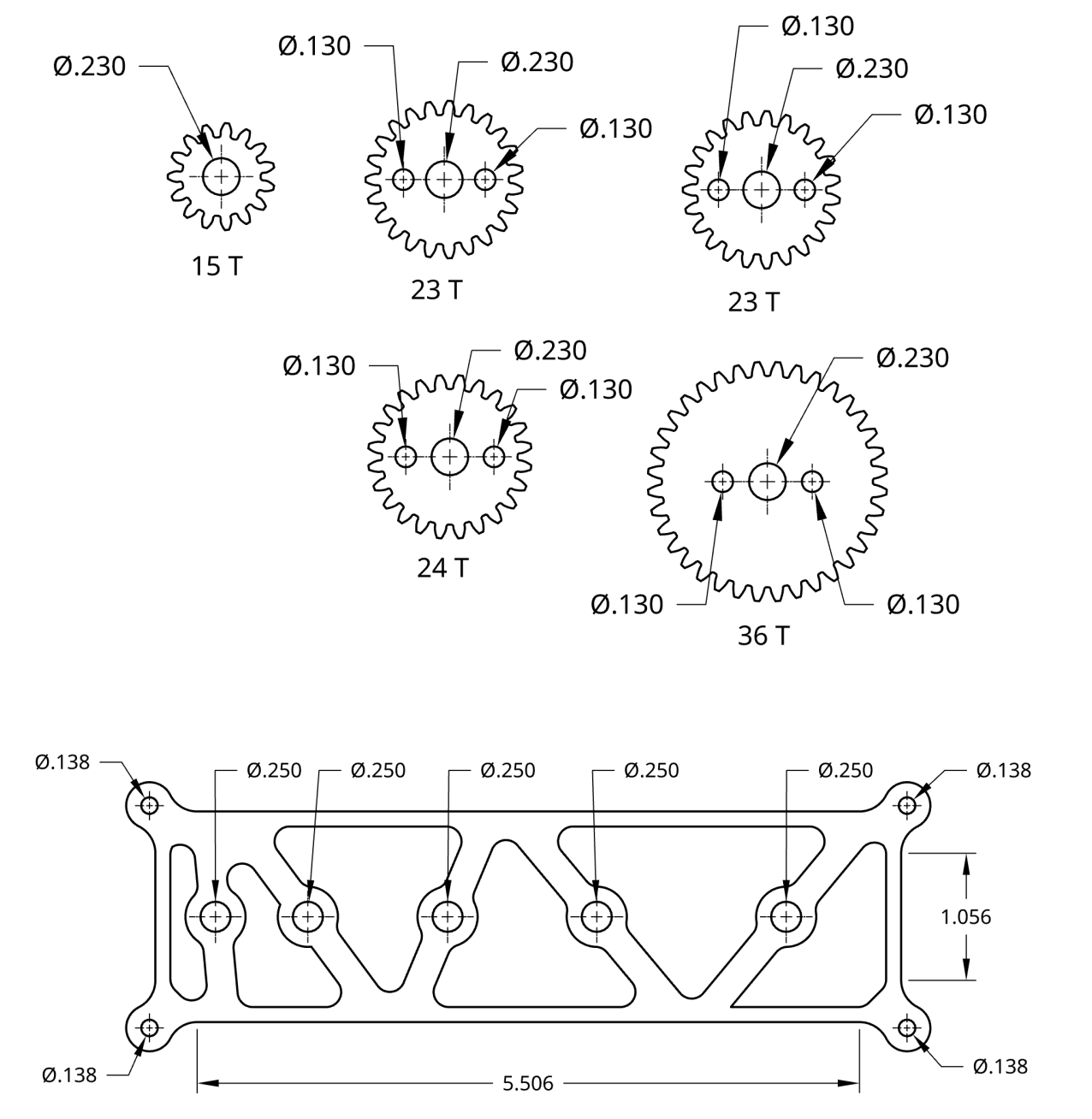

Our design features a large central gear driven by the motor's belt drive. Mounted on this main gear are smaller planetary gears that counter-rotate as the main gear turns. This creates a captivating, multi-layered "gears-within-a-gear" motion.

Key Mechanical Features

-

Belt Drive & Pulleys

A 3D-printed pulley system transmits power from the motor to the main gear assembly efficiently and quietly.

-

Cascading Gear Train

The main gear drives smaller gears, resulting in a complex and visually interesting motion from a single input.

-

Mixed-Material Assembly

The sculpture utilizes laser-cut plywood for the structural frame and gears, with 3D-printed components for pulleys and spacers.

-

Precision Manufacturing

Every part was carefully designed in Onshape and fabricated using tools like the laser cutter, 3D printer, and lathe for a precise fit and smooth operation.

Final Product.

Design & Fabrication Process

Ideation & Sketching

Our team brainstormed various concepts for motion, settling on the cascading gears idea for its visual appeal.

CAD Modeling

We designed the entire assembly in Onshape, simulating the gear interactions and ensuring all parts fit within the size constraints.

Multi-Tool Fabrication

We used a laser cutter for the plywood gears and frame, a 3D printer for the pulleys, and a lathe for custom shafts and spacers.

Assembly & Integration

The final phase involved assembling all components, mounting the motor, and tensioning the belt to bring the sculpture to life.

Tools & Technologies Used

Onshape (CAD)

Used for the complete 3D design, allowing for collaborative work and precise modeling of the intricate gear system.

Laser Cutting

Essential for fabricating the flat components like the main chassis and gears from plywood with high accuracy.

3D Printing

Used to create more complex geometric parts like the motor pulley and spacers, which would be difficult to machine traditionally.

Lathe

A manual lathe was used to create custom-sized shafts and axles, ensuring a perfect fit and smooth rotation for the gears.