Acronym: A Mechanical Automaton

A team project to design and build an automaton representing a unique aspect of Olin College—a coffee-making club named "Acronym."

View Project Portfolio →The Project Brief

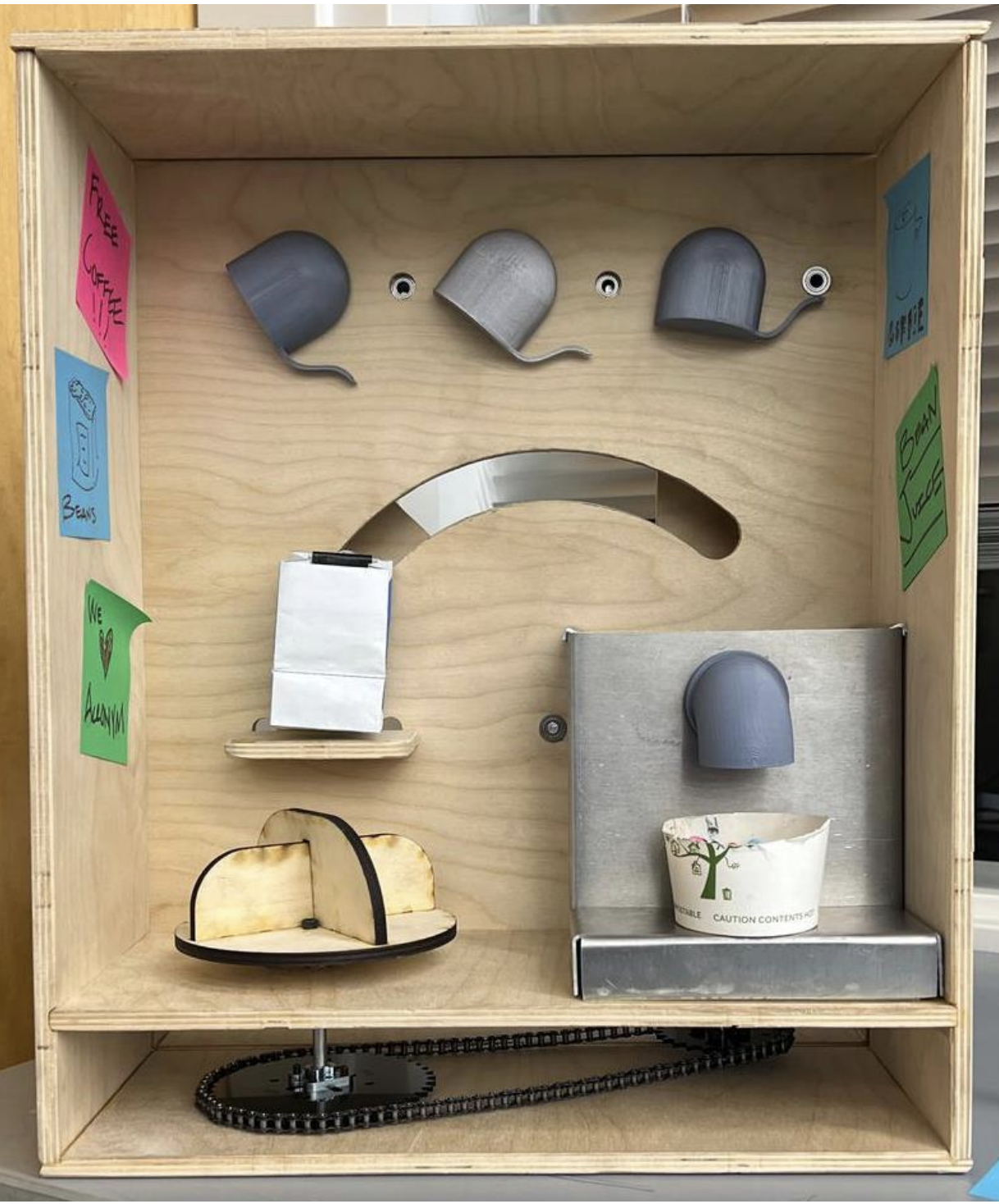

The core task was to work in a team to create a mechanical automaton that captured something unique about the Olin College of Engineering. Our team chose to build a homage to "Acronym," a student-run coffee-making club, by automating a miniature version of their supply cabinet.

Compact Design

The final build had to fit within an 18" x 18" x 8" volume and weigh under 15 lbs.

Mechanism Requirements

The design was required to include a chain drive, a rotational-to-rotational mechanism, and a rotational-to-translational mechanism.

Successful Outcome

Despite a motor failure due to high friction, all individual mechanisms were designed, built, and functioned as intended, meeting all design requirements.

Ingenious Mechanisms

The automaton integrates several distinct mechanical systems to create a dynamic scene simulating the coffee-making process.

Key Mechanical Systems

-

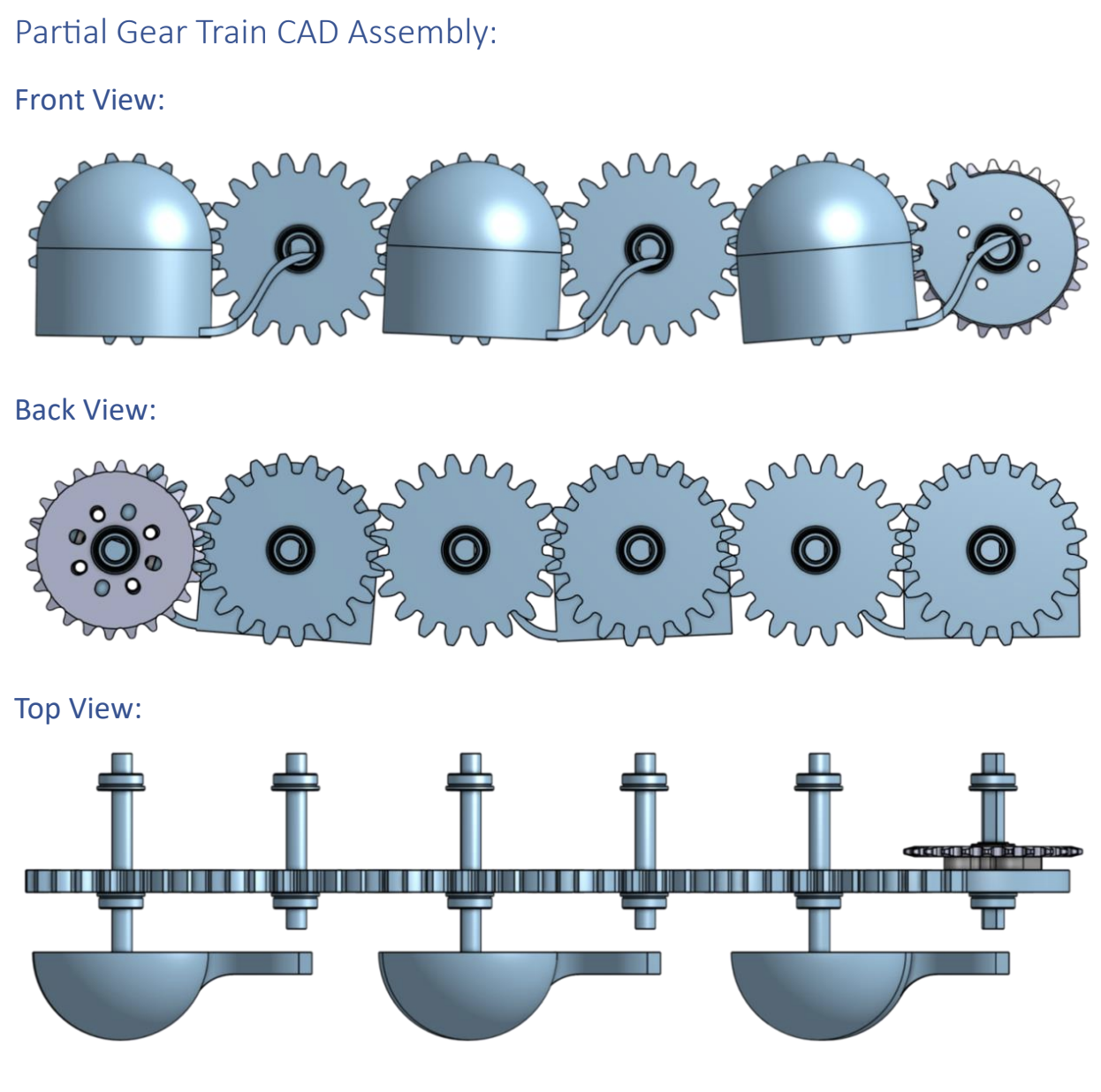

Partial Gear Train

A custom-designed partial gear train drives a set of "dancing" gooseneck kettles in a whimsical display.

-

Chain-Driven Lazy Susan

A chain drive (rotational-to-rotational) rotates a Lazy Susan carrying "coffee bags" filled with marbles.

-

2-Bar Linkage System

This linkage tips a coffee bag, causing it to dump its marble ("coffee") into the coffee machine.

-

Archimedes Screw

This mechanism (rotational-to-translational) lifts the marble and deposits it into a cup, completing the cycle.

The completed "Acronym" automaton.

Challenges & Learnings

Calculating Chain Length

To avoid manual measurement during assembly, the chain path was sketched in Onshape. Using the split tool, the exact required length was calculated beforehand, streamlining the assembly process significantly.

Designing Gooseneck Kettles

Creating the smooth, organic curves of the kettle necks was a challenge. This was solved by learning and applying the Bezier curve feature in Onshape, allowing for precise control over complex curved geometry.

Lathing Stainless Steel

Mistaking a stainless steel D-shaft for aluminum led to it work-hardening and snapping during lathing. This experience was a critical lesson in material identification and using the correct tools and machine speeds for the job.

Skills Developed

Advanced CAD

Gained proficiency in Onshape, specifically with creating partial gears, using derived features, managing variable studios, and modeling complex geometry with splines and Bezier curves.

Fabrication

Honed practical manufacturing skills through hands-on experience with the lathe and 3D printing, translating digital designs into physical components.

Engineering Principles

Developed a deeper understanding of designing for manufacturing (DFM) by considering assembly and material properties during the design phase, and practiced effective team collaboration.